As soon as you enter the print shop, you can hear the noise of machines. They rattle and clatter, and you are still two fire doors away from the action. Once in the hall, there is a special smell in the air. It smells of paint and solvents, chemical somehow. Unusual in any case.

The printing press plays loud melodies to inform you of its condition. When it has finished feeding and mounting the four printing plates cyan, magenta, yellow and black, it plays beautiful marching music. I was told that the alternate sounds were the sounds of a fax machine.

Anyway, with every march that was played, I knew that a new printing sheet was beginning. 26 times, without interruption. I hadn't known that they worked in two shifts, so it became a very long day for me.

All the employees were super friendly and I felt incredibly at home in the printing company. They offered me drinks and even brought me lunch. And I was given a table to wash individual printing plates and take them with me. My gallery owner turns them into special editions containing the book and framed original printing plates — genuinely unique pieces.

It's been five years since I last accompanied a printing process. I had forgotten how much manual work the printers do. I have the greatest respect for them! Although the machine costs several hundred thousand euros, it doesn't do everything by itself.

Print sheets have to be constantly removed and measured. The ink density has to be readjusted manually and any imperfections have to be rectified as quickly as possible.

And let's not forget that paint from pots has to be smeared onto the rollers manually. That surprises me every time. But somehow it makes sense. After all, the machines could also be filled with special ink pots outside of the CMYK color spectrum.

It all becomes particularly exciting when the process is switched from straight printing (which is called Schöndruck (beautiful printing) in German) the front sides of the 70x100cm print sheets to the reverse print (Widerdruck in German).

Then there is less scope for setting up the new sheets, the waste has to be quickly removed from the stack of sheets and everything has to be neatly documented.

So I approved the print sheets and helped to check that everything was OK. Of course, the printers could have done that on their own. But now I can sleep better because I was there and accompanied the entire process. Until everything was finished at 10 pm.

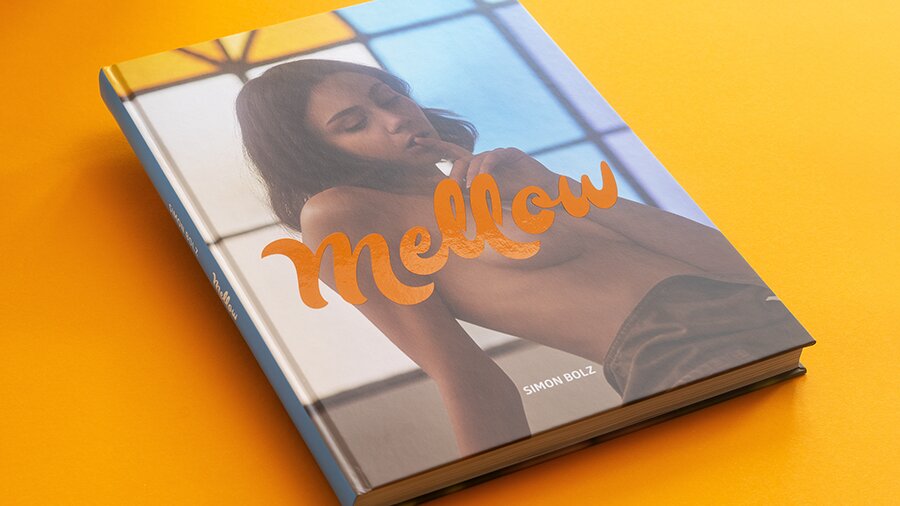

I also noticed that I look a bit tense in the video. Can't really blame me, though. Printing that book was a big deal for me. »Mellow« is kind of my baby. And the printing house was the delivery room, so to speak.

And you wouldn't believe it, but there were probably six or seven times when we thought there was an error in the print. Then we took a thread counter (a special magnifying glass) and checked. You can then immediately see whether it's an error in the print or whether the supposed culprit has been rasterized, i.e. is already included in my photo.

For example, there is a photo in which hard sunlight falls on a sharp-edged stone. The edge of the light is very sharp and therefore looks like a scratch on the paper. In other places, there were individual hairs sticking out of the model's head or a reflection of the marble floor in the chair leg.

It was incredibly difficult for me to get used to the colors I saw on the sheets. Not all the models have the same skin tone and I photographed them in different places under different lighting conditions. On a printed sheet, the pictures are not arranged in the order of the book, but (to put it simply) in a jumbled order. As a result, I sometimes had the feeling that the skin tones didn't match. I just had to put up with this false feeling, because in real life the colors were not wrong and I had checked them umpteen times beforehand.

There was also the confusion of the arrangement of the motifs. The sheets will be folded and trimmed later. Then they are correctly aligned. It's just too difficult for my brain to imagine this in three dimensions.

After printing, the paper had to rest for a while and was then taken to the bookbindery. Since the beginning of this week they are taking care of finishing the illustrated book — again by hand. I expect to be able to begin packaging books next week.

Pre-sale is finished on March 15th. To save € 17, you need to place your order now.